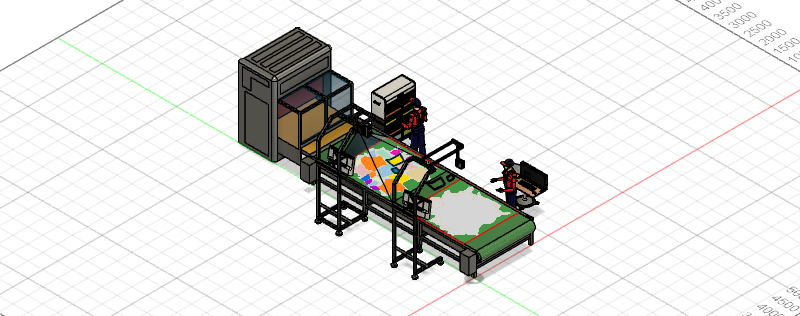

GANIROLLER - Roller Press Cutting Machine

GANIROLLER is digital add-on for your roller press die cutting machine. It comes with

projector table which projects 1:1 scale nested hide profiles from our GaniNest Software.

Brochure

Download our brochure to explore our products, solutions & services we provide

LET’S OPTIMIZE YOUR PRODUCTION

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

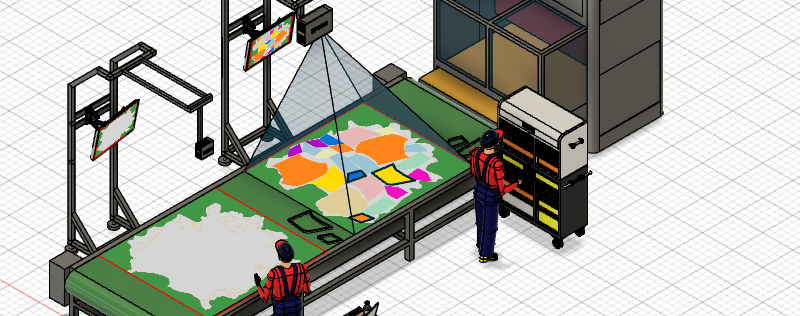

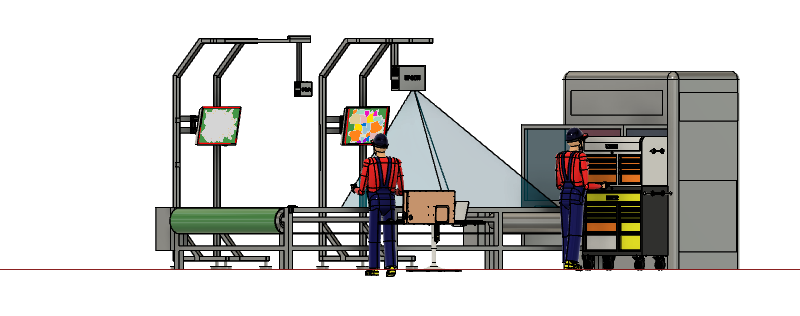

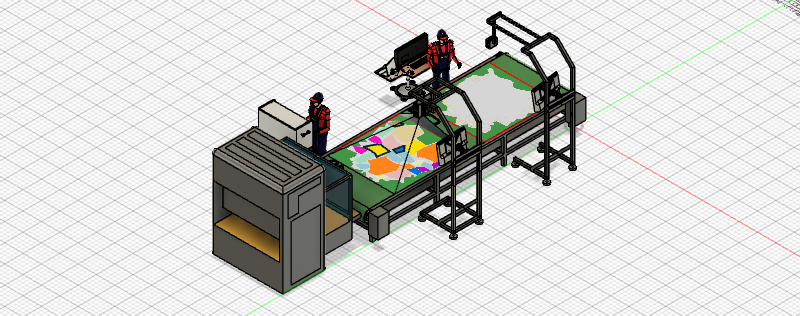

GANIROLLER - Roller Press Cutting Machine

Roller press die cutting is one of the fastest way to make batch production but the efficiency of raw materials usage is very low due to strenuous manual activity required for doing manual nesting. GaniRoller helps to solve this with the help of GaniNest and GaniProjection softwares.

How GaniRoller helps?

GANIROLLER is digital add-on for your roller press die cutting machine. It comes with projector table which projects 1:1 scale nested hide profiles from our GaniNest Software. This add-on keeps the cutting speed of your roller press and improve the efficiency of nesting. The highest utilization of material with projection of nested pieces saves your time and money.

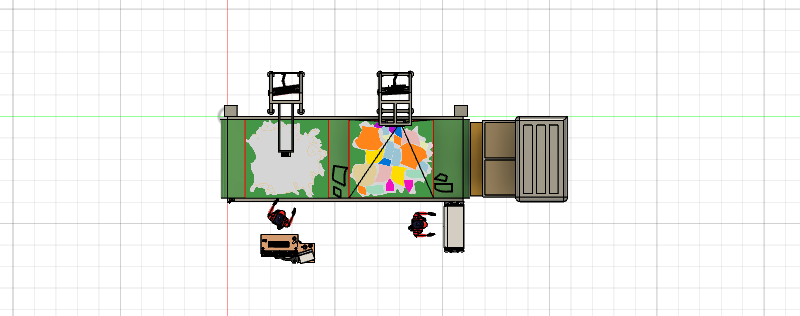

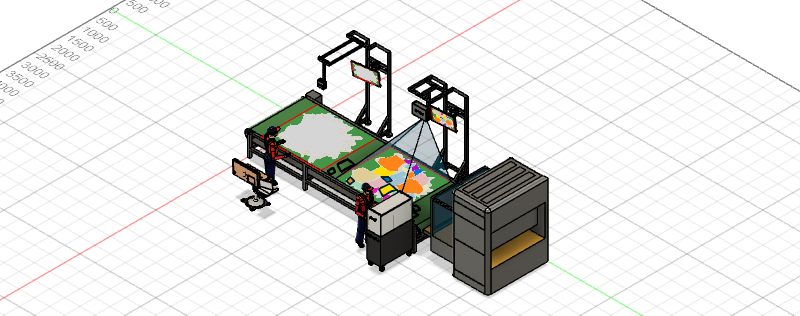

Four steps to upgrade your existing roller press

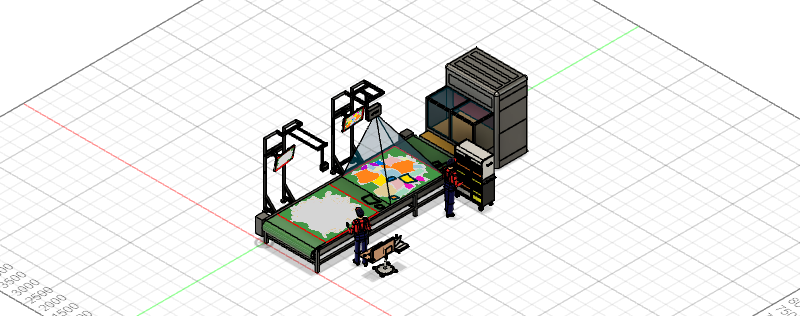

GaniPattern

Photo-digitization or Import of Patterns

Fast & Easy way to input patterns to the database

GaniScan

Photo-digitization Leather Profiles

Digitization of leather hides using DSLR Camera

GaniNest

Automatic Nesting Station

Fully automatic nesting with the highest utilization of material.

GaniProjection

Projection of Nested Dies on Material

Projection of nested pieces enables quick and simple placement of dies on material.

Industries suitable for this solution

Features

Flatbed knife cutting machine is integrated with our GaniNest software through plugin

Nested hide profile patterns can be projected 1:1 scale on the cutting table for aligment.

Scanning of leather with quality zones and defects. Interactive defect marking is provided.

We provide documentation and training for easy maintenance without breaking your production schedules.

It provides fast and accurate cutting to 2 mm to 4 mm divergence maximum.

Post installation we have dedicated support teams where we assure you to resolve issues faster with SLA agreed.

It can commissioned with both static and conveyor belt

Statistic and analytics information on production from roller press

Vaccum zone can be efficiently controlled based on the hide profile areas so that grip is more.

Entire system is easy to setup and get trained under a week. Instant remote support available